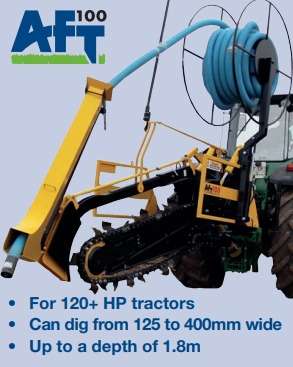

AFT Trenchers manufacture tractor-mounted and PTO-driven attachment trenchers in the UK.

Their trenchers are simple to operate with minimal maintenance requirements, making them ideal for any tractor driver.

They can cut the narrowest trench possible to improve productivity and reduce back filling costs.

We recently spoke to CG Warner Limited about agricultural drainage and trenching

What is so important about agricultural drainage?

“You need to understand that without efficient drainage yield loss is inevitable.

“You need to understand that without efficient drainage yield loss is inevitable.

On an average 600 hectare farm I would suggest that up to 40 hectares would benefit from some form of land drainage to improve yields by up to 25%.

This 25% yield improvement will result from addressing the cumulative effects of:

- machines travelling across the wet arable lands

- weeds and grasses that favour wet ground which would be hard to control even with expensive herbicides

- timeliness of cultivation

- establishment of the crop due to poor root development

- leaching of fertiliser due to run-off

- fungal diseases due to excess water

- uneven ripening

So on a winter wheat crop yielding ten tonnes per hectare, a 25% loss in yield equates to 2.5 tonnes per hectare at £300 a tonne. This equates to £750 per hectare multiplied by 40 hectares, giving a potential loss of up to £30,000 in ANNUAL income.”

What benefits do you get from your AFT100 trencher?

“Output – I can outperform a conventional digger by at least 250%, often 300 to 400% if the conditions are favourable.

Ease of backfill – I can dig the trench size I need, rather than 30cm with a conventional digging bucket, which is more cost effective if using aggregate on top of the land drain.

Trench gradient – The ability of being able to use an automatic laser system with the AFT trencher enables me to follow a pre-determined gradient to install an effective drainage scheme.

Maintenance – The simple design of the machine allows for all maintenance to be undertaken by the operator on-site without specialist tools and equipment.”

Why did you buy an AFT100 trencher?

“Being involved in a root crop which is harvested in the winter months, it was of paramount importance to have land in good condition to harvest the root crop and to establish the following wheat crop.

“Being involved in a root crop which is harvested in the winter months, it was of paramount importance to have land in good condition to harvest the root crop and to establish the following wheat crop.

Farming is all about timeliness. The AFT100 allows the work to be done when the farmer or contractor can utilise labour to install the drains at a convenient time to suit themselves and their field conditions, as opposed to pre-booking a self-motorised trencher several weeks in advance.

I have four different machines from AFT which cover the varied contracting services I offer.”

Do you have any comments on the running costs of the AFT100?

“I ran the machine until a complete refurbishment was necessary of all wearing parts after 40000 + metres. This resulted in a cost per metre of £0.20 plus in-house labour of two days.

The trencher is designed to run at a PTO speed of 540 RPM at an engine RPM of 2100. But on modern tractors it is possible to run the PTO speed at 1000 RPM with the engine RPM at 1100. This equates to 540 RPM output on the PTO shaft and results in a significant saving on diesel consumption.”

Finally, what is your experience with AFT as a Company?

“The back-up service and spares availability are second to none.

The machines purchased have proved to be very cost effective and reliable.

The Company was created in the UK 50 years ago and I have known the staff for over 20 years.

In my experience the team at AFT will go the extra mile to be of assistance to their customers.”

CUSTOMER EXPERIENCE:

CUSTOMER EXPERIENCE:

DRAINAGE & IRRIGATION CONTRACTOR

CG Warner Limited is a well- established agricultural contractor with a strong track record of over 50 years of experience in the UK.

In addition to their expertise in lifting and drilling 1200 hectares of sugar beet annually, CG Warner is also an experienced drainage and irrigation contractor.

Other services include sports ground drainage and civil works such as fibre optic cabling, ground source heating, and water installations.